What Does American Plastics Do?

Table of ContentsOur American Plastics PDFsGetting My American Plastics To WorkThe 3-Minute Rule for American PlasticsThe Best Guide To American Plastics7 Simple Techniques For American Plastics

A little research can help you in time. It is difficult to judge its top quality in the beginning glance with the appearance of HDPE pipe fitting, numerous defects are exposed when making use of, so we can only have an appropriate judgment after use. As a result, it is required to choose HDPE pipe fittings made by a specialist producer with a great online reputation and track record.

A technical professional is important for a great product, especially in the manufacturing market, due to the fact that a small blunder will certainly cause the failure of the entire project. HDPE pipes can change concrete pipelines in field systems to conserve time and price of fixing busted or burst pipelines. HDPE pipeline is also a cheaper choice contrasted to various other piping products in regards to operating and setup prices.

The smart Trick of American Plastics That Nobody is Talking About

HDPE pipelines are manufactured with solid straight or rounded sections. The pipelines are not fragile and can be quickly put right into a bent area without added jointing or welding.

It has low stress and stormy disturbance, particularly at high circulation prices. Its 'non-adhesive' particular makes it perfect for preserving the residential or commercial properties of hydraulic fluids. Even HDPE tin tubes are formed in two stages to ravel the interior. Chemicals immune to HDPE pipes can contaminate the pipe. The pipeline does not deal with chemicals and does not shed heat or electrical energy.

HDPE pipes are naturally solid and immune to damage triggered by exterior loads, high stress or resonance - https://giphy.com/channel/americanplastics. The pipes can withstand handling and bend also in cool weather. Safe eye liner HDPE internal tubes Smooth Line Pipeline Moving lining making use of roller mixes Pipe surge Plastic plumbing systems Building of brand-new pipes Corrosion resistance, no dripping, high longevity

Warm integration, while its difficulties exist, can create solid and dependable joints. Solutions: The strength and durability of HDPE can be measured by its ability to hold up against temperature levels of around 248F in the short-term or also a continuous 230F. If your application consists of gas and liquid to accessibility and elevate those temperatures, HPDE piping is a trustworthy service.

What Does American Plastics Mean?

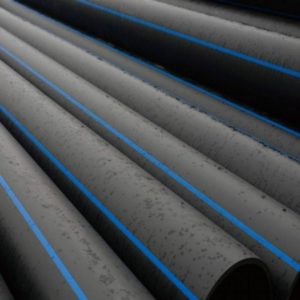

A drinkable water line/potable water pipeline is constantly dark with blue red stripes and pipes passing via fluids, liquids under stress, and procedure gases are always loaded with a yellow or black jacket with yellow lines. HDPE pipe material have been utilized in the basic market for over 50 years and their results are astonishing, developing confidence among manufacturers that they are extra concentrated on HDPE pipeline options.

Times considering that 1991 Removal of material requirements with gauge and change. In the stress fracture resistance examination the cellular division demands were compromised. Therefore, it is practical in conclusion that HDPE pipeline constructed today may have.

Each size group is created keeping in mind the demands of stress, flow price, and environmental elements of the intended application. By matching the correct HDPE pipe dimension to its use, engineers and contractors can enhance efficiency and prolong the life expectancy of their piping systems. Dimension and diameter i was reading this are interrelated concepts in the context of HDPE pipes.

A Biased View of American Plastics

As specified earlier, pipelines with lower SDR worths are able to hold up against greater pressures, which is an essential consideration in the selection process for projects that include high pressure or essential applications. custom hdpe pipe manufacturing Midland TX. Picking a pipe with an unsuitable SDR could cause system failure, safety and security threats, and costly fixings. Selecting the proper HDPE pipeline size is important for the success and performance of any piping system

Application Specifics: Tailor your pipeline dimension choice to the certain needs of its application, whether for local, commercial, or other uses. Understanding just how the HDPE pipeline will certainly be utilized, the anticipated flow rates and the pressure needs are vital. For instance, high-pressure applications could require a pipe with a better wall thickness to stand up to the internal tensions, while a lower-pressure, high-flow system could prioritize diameter dimension to minimize friction loss.

Not known Incorrect Statements About American Plastics

Comply with these actions: Analyze the Application: Establish the pipe's planned usage, consisting of ecological aspects and solution problems. Refer to SDR: Check the standard dimension proportion to discover a pipe that can deal with the required stress.

Picking the ideal HDPE pipe dimension is a fragile equilibrium in between many technical requirements and sensible requirements - https://www.twitch.tv/americanplastic/about. However, with cautious factor to consider and exact estimations, you can ensure the size of the pipeline you select will certainly offer your needs successfully and effectively. Selecting the proper HDPE pipeline size is crucial for system effectiveness, durability, and cost-effectiveness

Understanding these facets will certainly make certain optimal efficiency and compatibility throughout your piping system - custom hdpe pipe manufacturing Midland TX. The expected flow price or volume of the liquid being moved is one of the main determinants in pipeline size option. A pipeline that is as well little can limit circulation, triggering pressure loss and potential clogs, while an overly large pipeline might bring about unnecessary expenditure and minimized system effectiveness